Factory Online Energy Monitoring Solution deployed in a certain factory in Saudi Arabia

Apr 11, 2023

0.Project Background:

One of our party A customers in KSA want a entire Online Energy Monitoring Solution (mainly of electricity) for their factory machines. Their basic

requests are "remote meter reading", "auto-generated daily&monthly&yearly energy consumption report for every machines and factory's overall power

consumption". In other words, they want to realize a digitalization of energy monitoring for their all factory machines so that they could set up energy

saving plan accordingly.

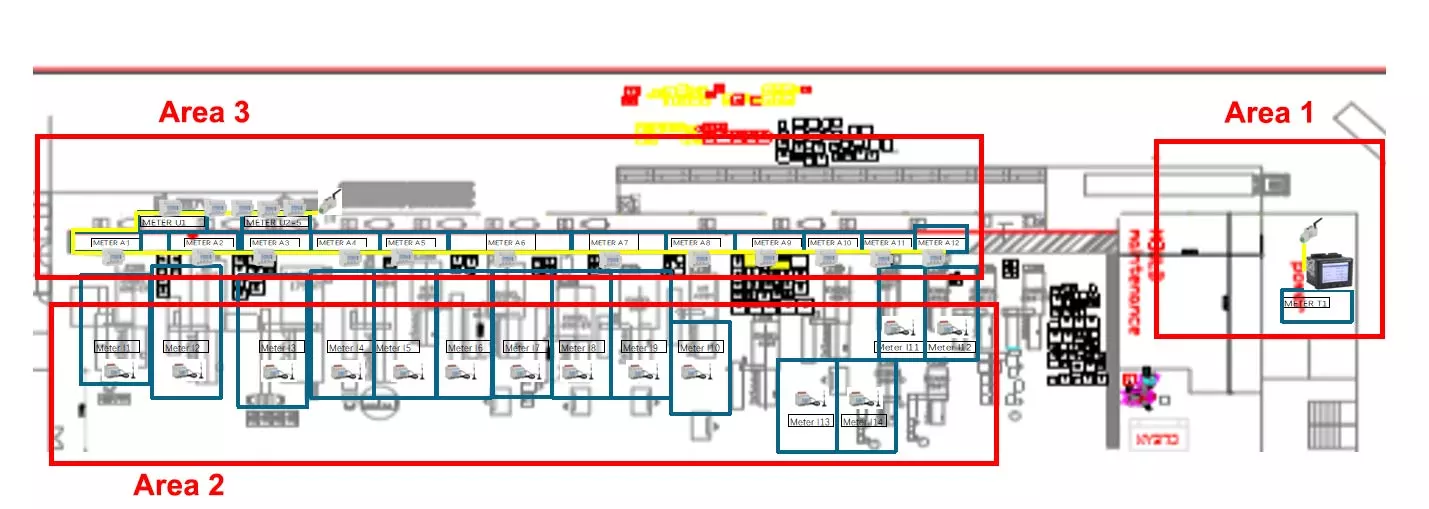

1.Factory Overview:

(1) The factory could be devided into 3 Areas for power consumption monitoring.(2) Area 1 was Main Power Distribution Room. Only 1 main incoming circuit 3-phase here need to be monitored. Circuit's rated current is 2500A

AC and its rated voltage is 3x400Vac L-L&3x230Vac L-N. Meanwhile, the circuit was carried by busbar with the size of 110mm*50mm (Cross

Section).

(3) Area 2 was 1st workshop with 12 machines 3-phase needed to be monitored. Each machine was powered by 1 circuit 3-phase. Circuit's rated

current is 400A AC and its rated voltage is 3x400Vac L-L&3x230Vac L-N. Meanwhile, the circuit was carried by cable with the size of 30mm

(diameter).

For Area 2 machines' distribution, each machine was far from each other, thus when we install the energy meters, all the energy meters will be

of separate installation and were also far from each other.

(4) Area 3 was 2nd work shop with 18 machines 3-phase needed to be monitored. Each machine was powered by 1 circuit 3-phase. Circuit's rated

current is 200A AC and its rated voltage is 3x400Vac L-L&3x230Vac L-N. Meanwhile, the circuit was carried by cable with the size of 20mm

(diameter).

For Area 3 machines' distribution, each machine was close to each other. So all the energy meters could be of centralized installation in a DB

cabinet.

(5) Both 3 areas are covered by stable 4G signal. Meanwhile, WiFi or Ethernet communication was not available for these areas.

-Area Overview Sketch (To Protect the privacy of customer, only sketch available)

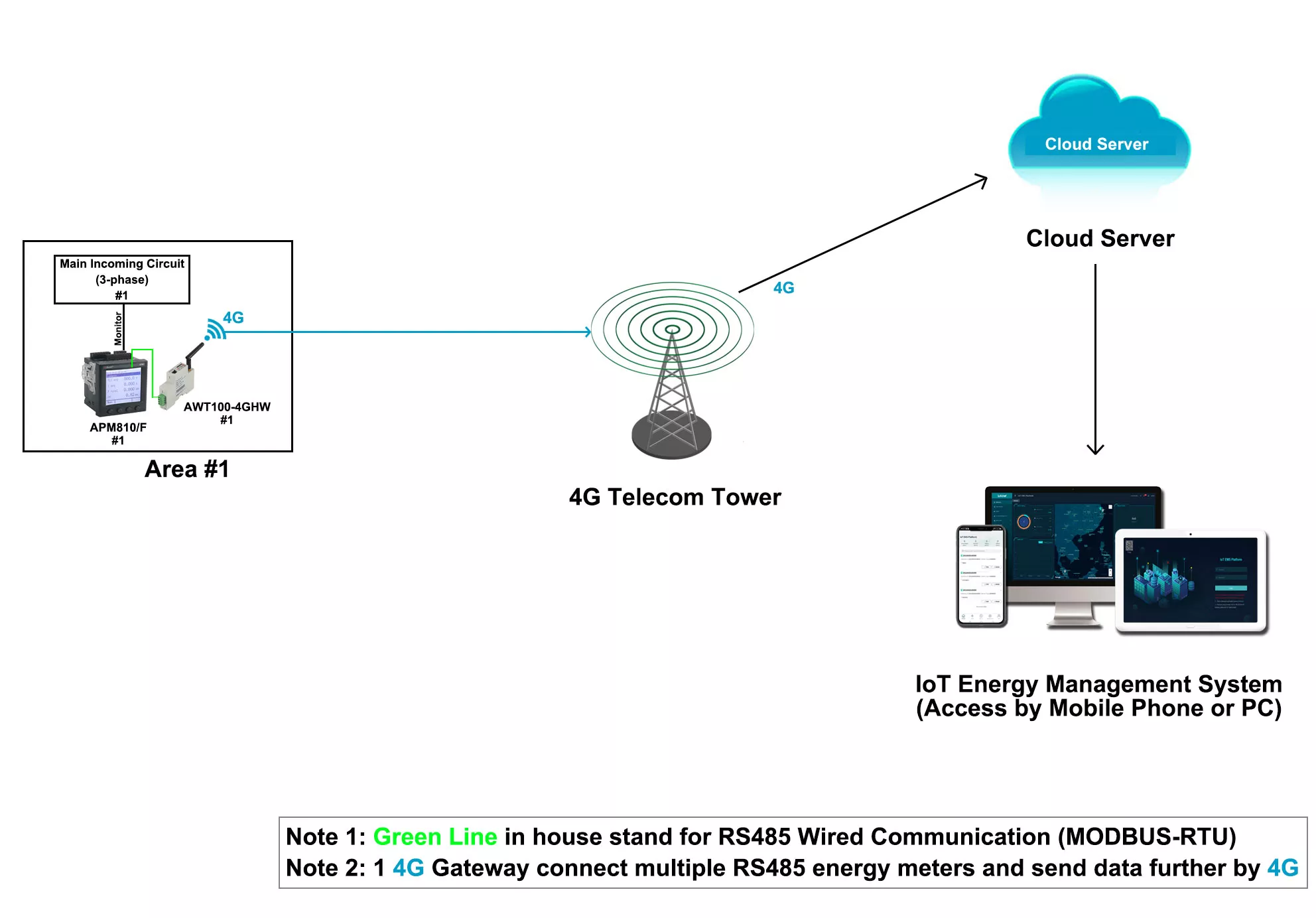

2.1 Devices Deployment Plan - Area 1:

Area 1 was for main incoming circuits monitoring.

Select model APM810/F 3-phase high-class energy meter for overall 3-phase power monitoring. (Full power quality Monitoring, such as 2st~63rd harmonic and etc.)

Select model AKH-0.66/K K-120x602500/5 current transfomer to be paried with APM810/F for 3-phase current input. (Suitable for busbar with size 110mm*50mm and rated primary current 2500A AC)

Select model AWT100-4GHW IoT 4G Gateway to be paired with APM810/F for further uploading the data collected by energy meter to cloud server via 4G communication

Area #1 - Main Incoming Circuit #1:

- 1* AWT100-4GHW iot 4G Gateway

- 1* APM810/F3-phase High-Class Energy Meter

- 3* AKH-0.66/K K-120x602500/5 Split-core Current Transformer.

- Area 1 Device Deployment Illustration

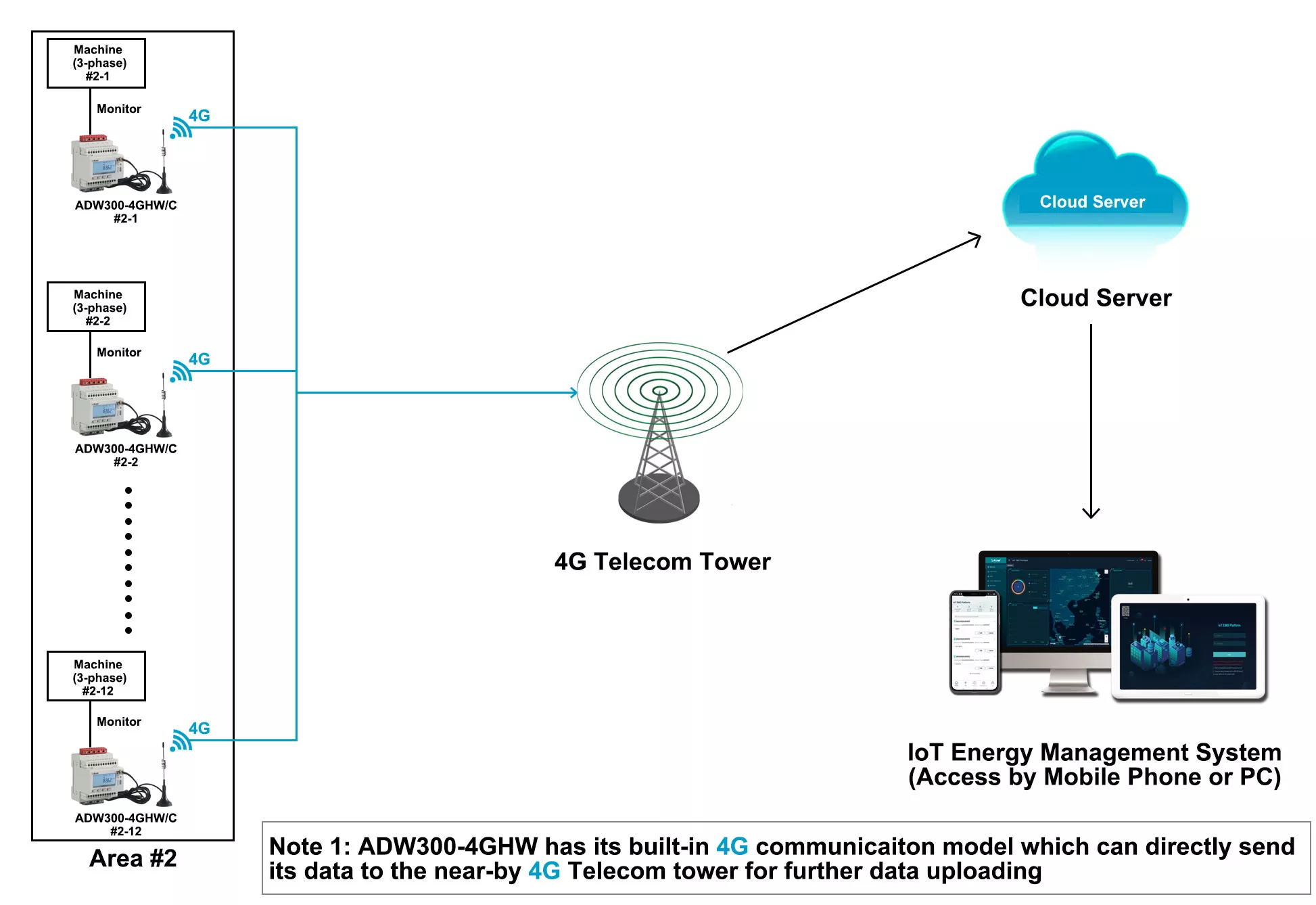

2.2 Devices Deployment Plan - Area 2:

Area 2 was for separate placed 3-phase machines monitoring.

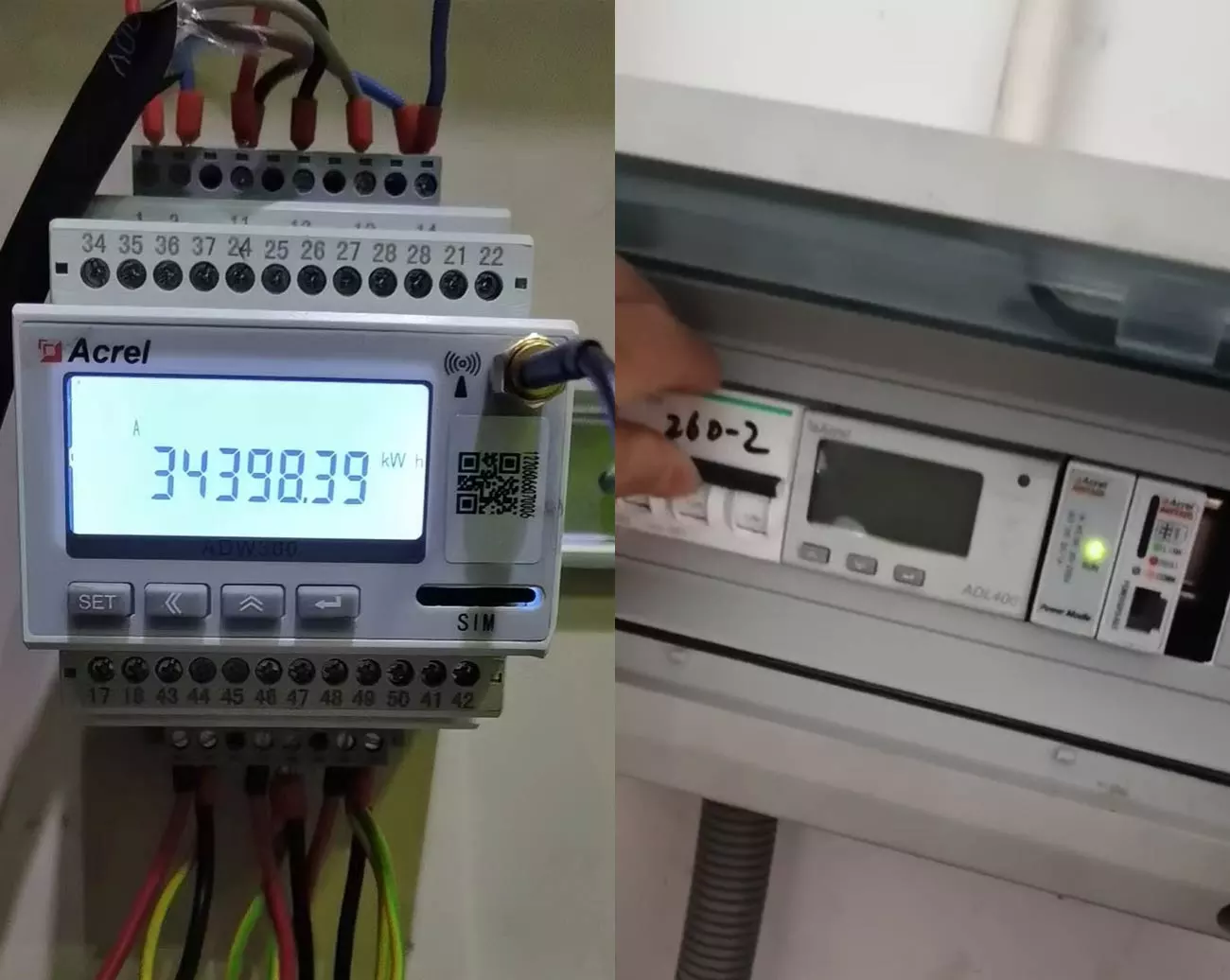

Select model ADW300-4GHW 3-phase 4G wireless energy meter for monitoring each separate machine. (ADW300-4GHW is with built-in 4G communication module, so doesn't need extra 4G gateway for further uploading the data through 4G communication)

Select model AKH-0.66/K K-φ36 400/5 current transfomer to be paried with ADW300-4GHW for 3-phase current input. (Suitable for cable with szie 30mm diameter and rated primary current 400A AC)

Area #2 - Machine #1:

- 1* ADW300/4GHW 3-phase 4G Wireless Energy Meter

- 3* AKH-0.66/K K-φ36 400/5 Split-core Current Transformer

.

.

Area #2 - Machine #12:

- 1* ADW300/4GHW 3-phase 4G Wireless Energy Meter

- 3* AKH-0.66/K K-φ36 400/5 Split-core Current Transformer

- Area 2 Device Deployment Illustration

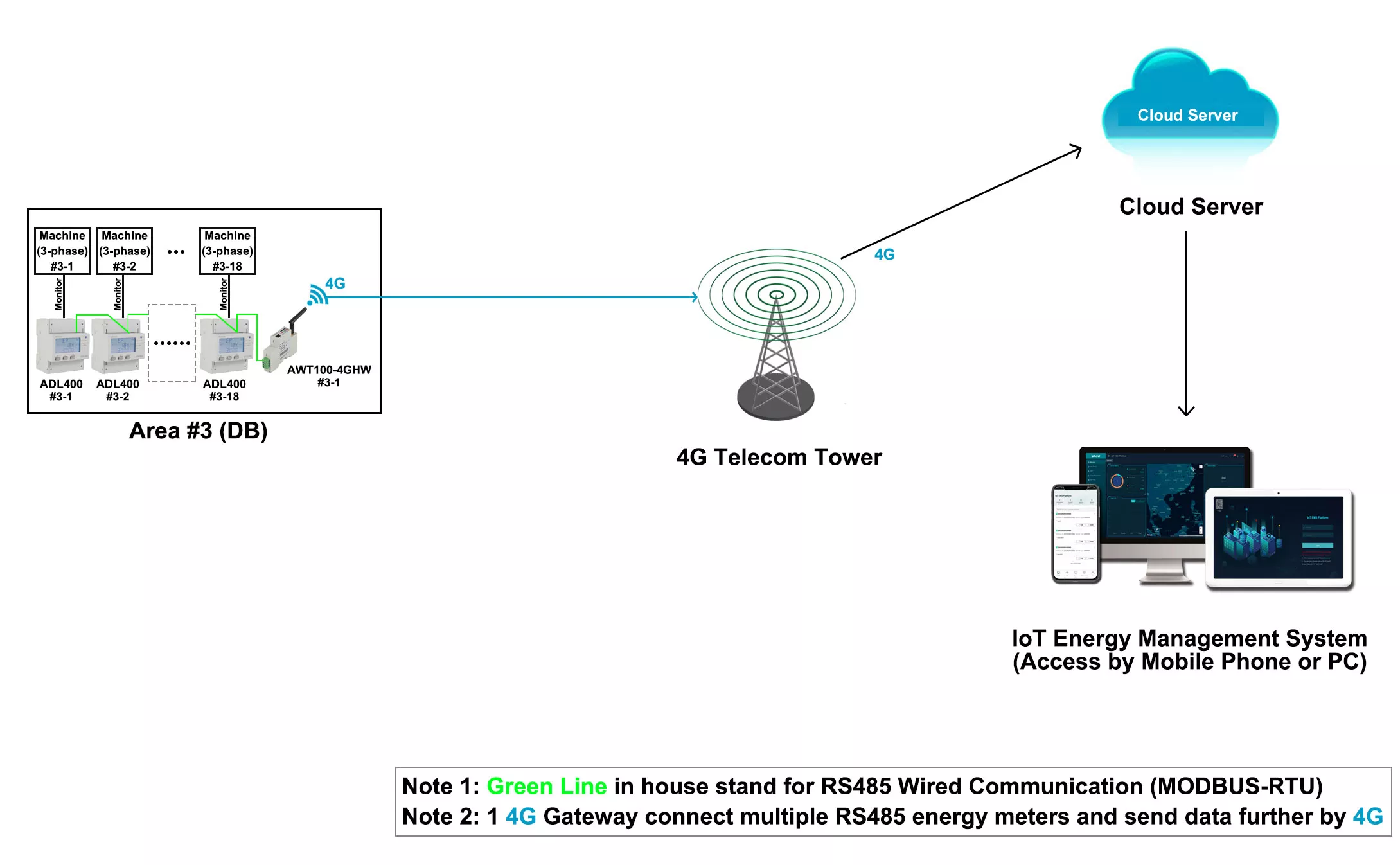

2.3 Devices Deployment Plan - Area 3:

Area 3 was for centralizedly placed machines monitoring.

Select model ADL400/C 3-phase energy meterfor each 3-phase machine's power circuit monitoring.

Select model AKH-0.66/K K-φ24 200/5 to be paired with ADL400/C for 3-phase current input. (Suitable for cable with size of 20mm and rated primary current of 200A AC)

Select model AWT100-4GHW IoT 4G Gateway to be paired with ADL400/C for further uploading the data collected by energy meter to cloud server via 4G communication. (1 AWT100-4GHW could support up to 25 ADL400/C energy meter using RS485 communication)

Area #3 - Overall:

- 1* AWT100-4GHW IoT 4G Gateway

Area #3 - Machine #1:

- 1* ADL400/C 3-phase Energy Meter

- 3* AKH-0.66/K K-φ24 200/5 Split-core Current Transformer

.

.

Area #3 - Machine #18:

- 1* ADL400/C 3-phase Energy Meter

- 3* AKH-0.66/K K-φ24 200/5 Split-core Current Transformer

- Area 3 Device Deployment Illustration

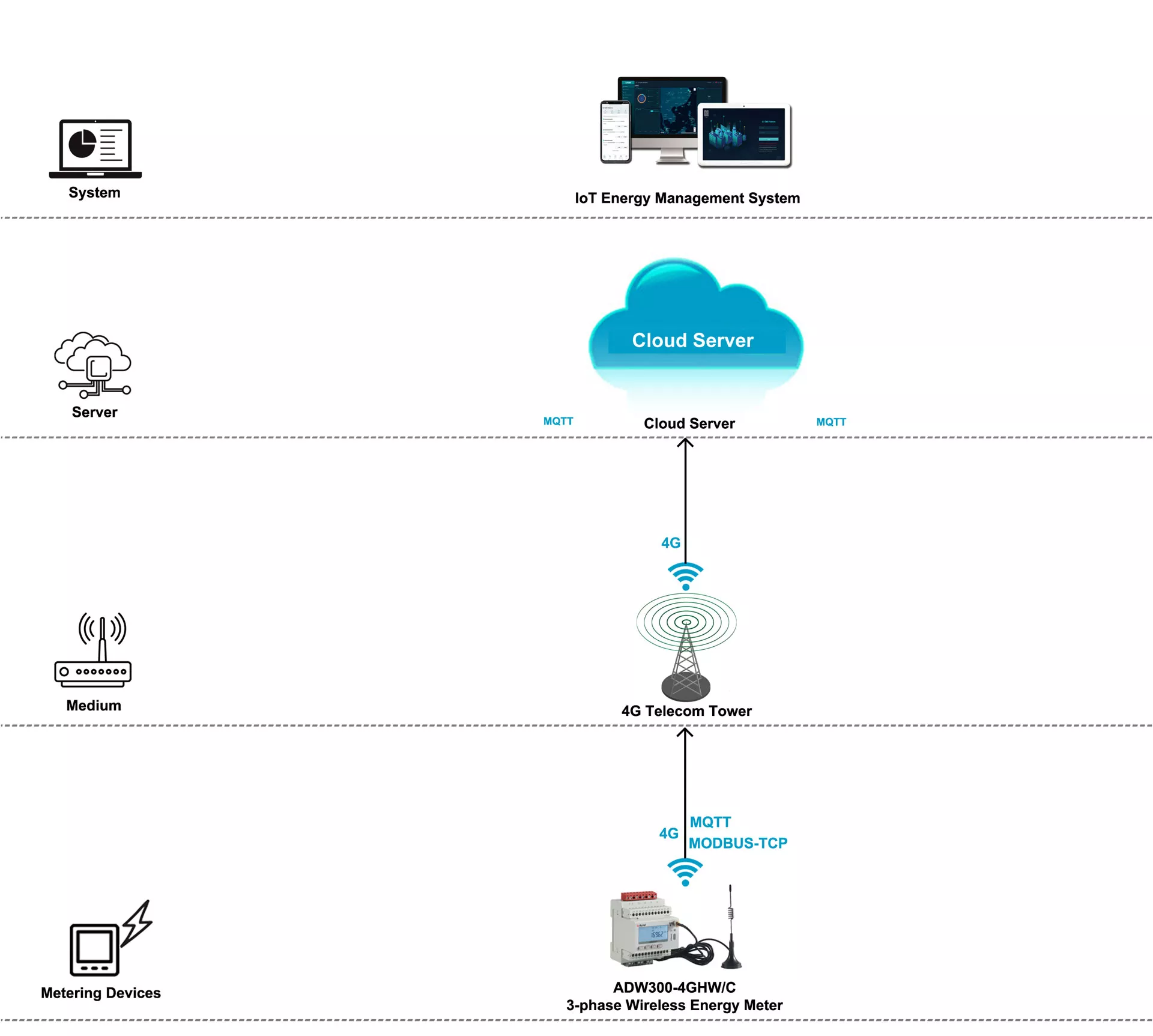

3.1 Communication Structure&Logic - Wireless Energy Meter:

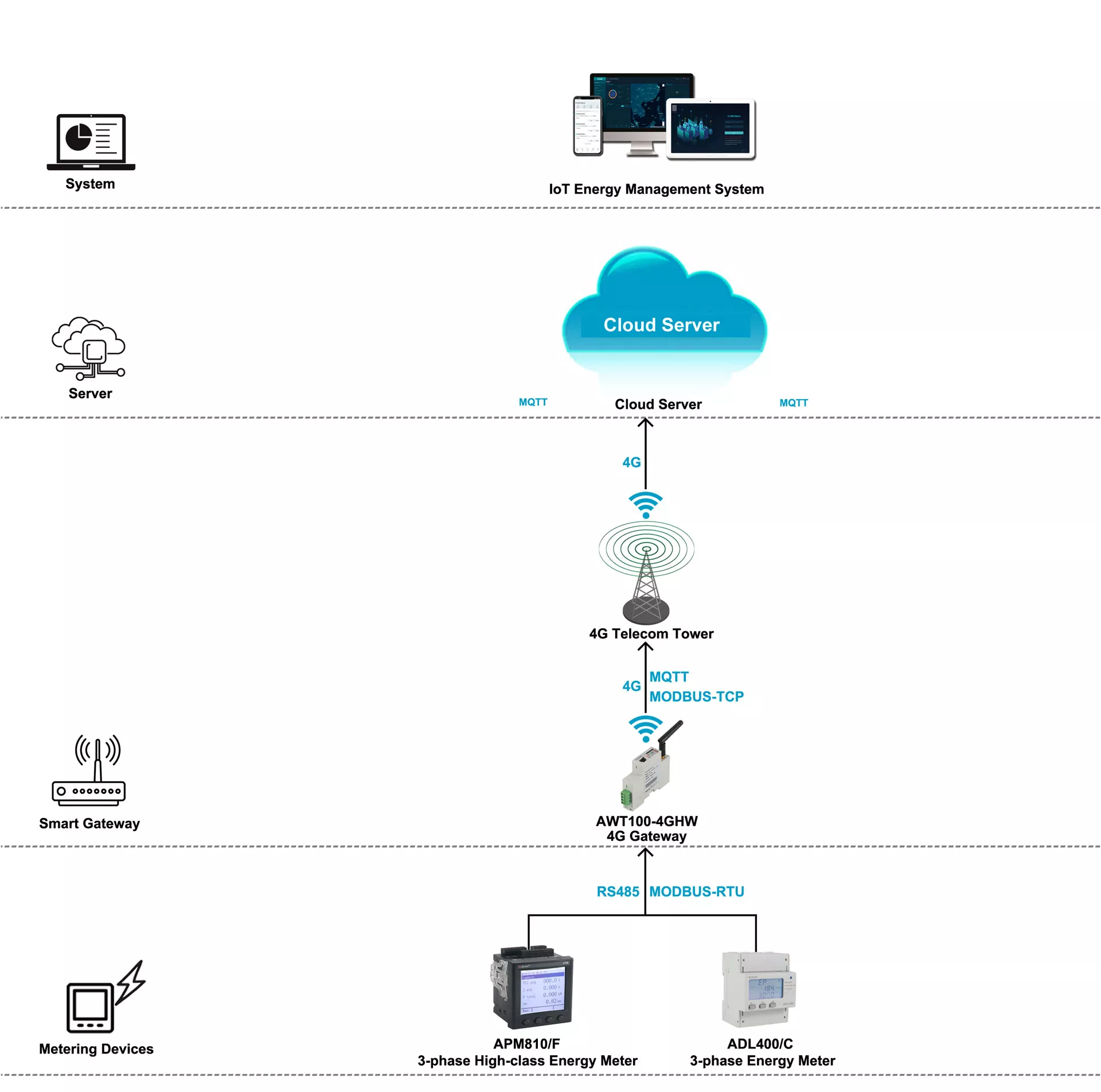

3.2 Communication Structure&Logic - RS485 Energy Meter paired with 4G IoT Gateway:

4.Project Landing Status:

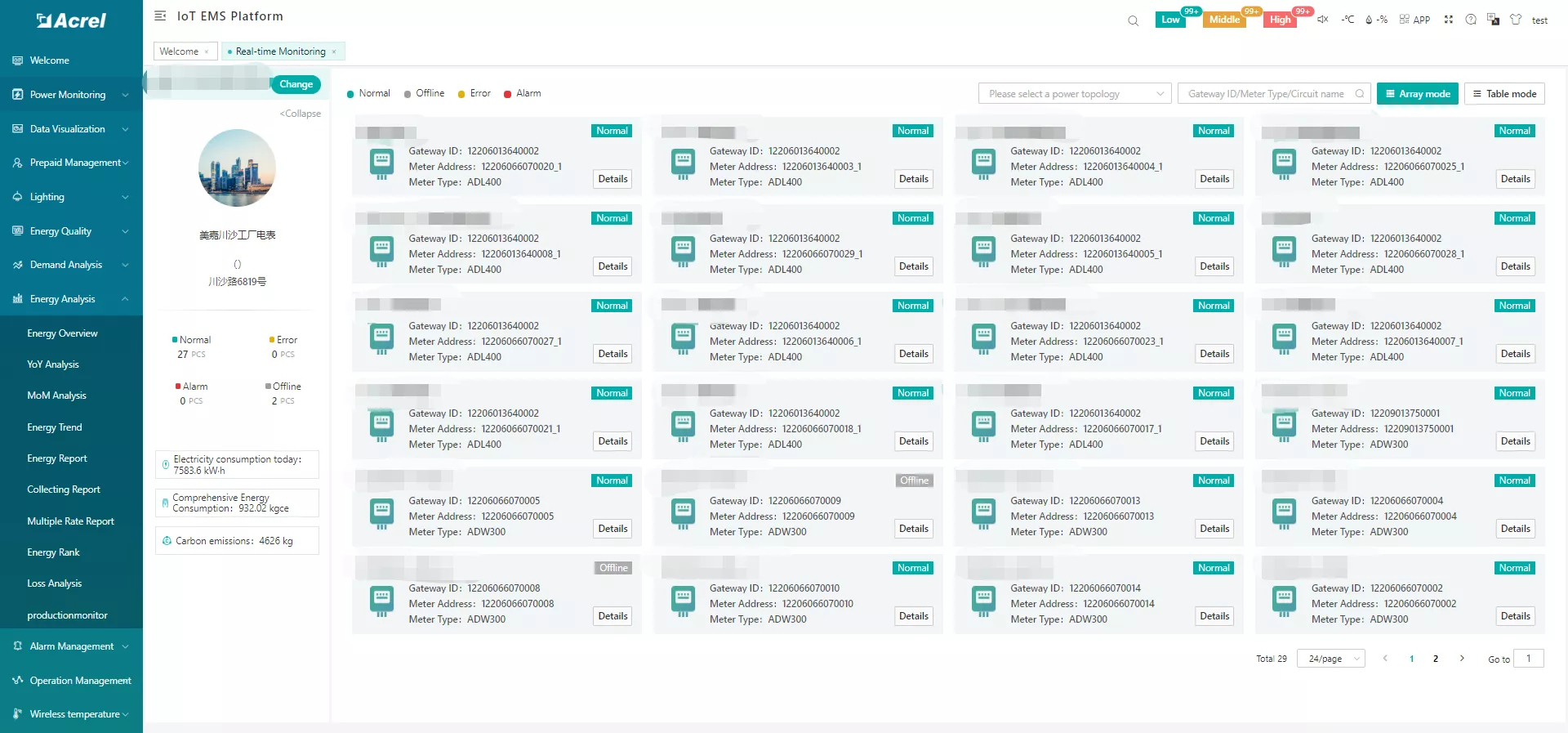

[1]. Devices List Showing on Energy Monitoring System [Partial Mosaic Censored]

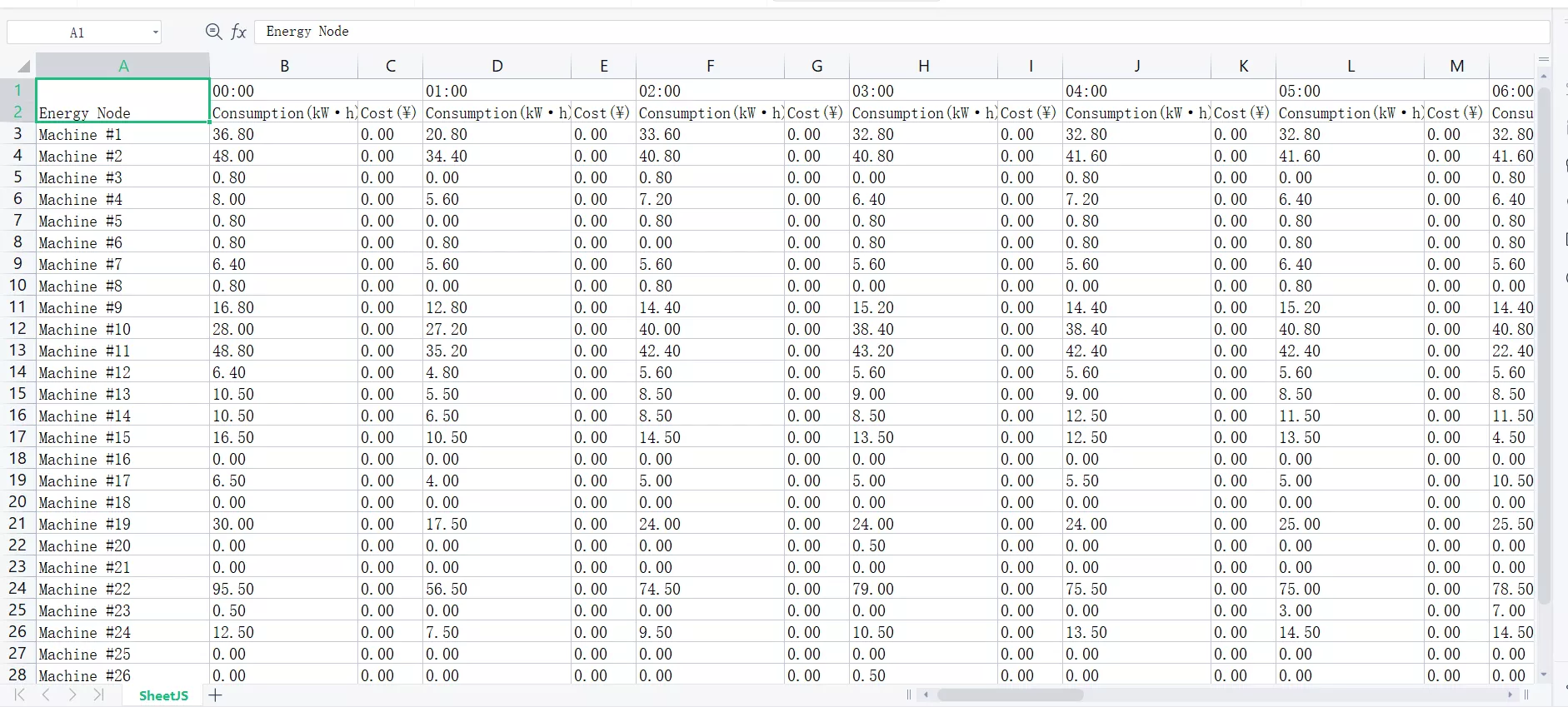

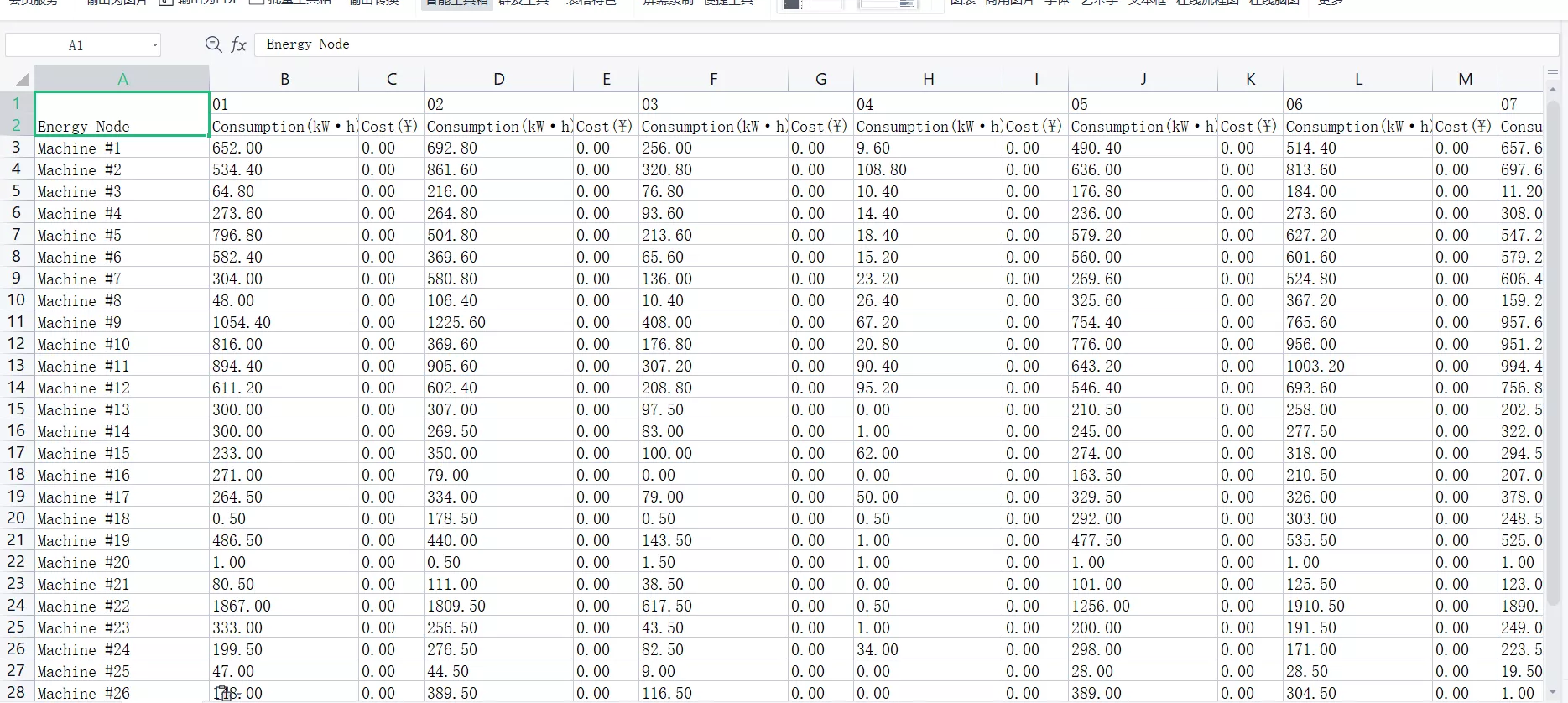

[2]. Auto-generated Daily Energy Consumption Report [Partial]

[3]. Auto-generated Monthly Energy Consumption Report [Partial]

[4]. Site Installation [Partial]

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jan 15, 2024

Wireless Temperature Monitoring in the Philippines

Jul 20, 2023

Energy management system Application in Cadillac