Acrel energy management solution for Shuanghui First Industrial Park

Sep 25, 2025

Shuanghui First Industrial Park is located in Luohe City, Henan Province. It is the earliest park built by Shuanghui Group and also the largest meat processing industrial park in China.

It covers an area of 1,500 acres and has an annual sales volume of more than 20 billion yuan. The industrial park was built in the 1990s, and the first batch of power supply and distribution facilities have been in use for nearly 30 years. As the scale of the park continues to expand, the power load has also increased, the cumulative capacity of the transformer has reached 64,000 kVA, and the related power supply and distribution facilities and equipment have also increased.

In order to ensure the reliability and safety of power supply and distribution in the entire park, Shuanghui Power Company adopts a three-shift manual regular inspection method, with operation and maintenance personnel on duty at the substation for a long time. The following problems exist: The park is large, with many substations, and the manpower cost of sending people to guard for a long time is high; Traditional visual inspections have low frequency, are difficult to detect problems, and are inefficient; Some hidden dangers are difficult to detect visually, and there are many blind spots in inspections; The inspection process was not standardized, and the key power supply and distribution equipment was not inspected in accordance with power standards through paper records; The important power supply and distribution facilities have incomplete information, lack of detailed repair, electrical testing and maintenance records, and the equipment is not properly maintained and operates beyond its service life; The operating data and alarm records of each substation exist in isolation and are not summarized, making it impossible to centrally and uniformly grasp the power supply and distribution situation of the entire park;

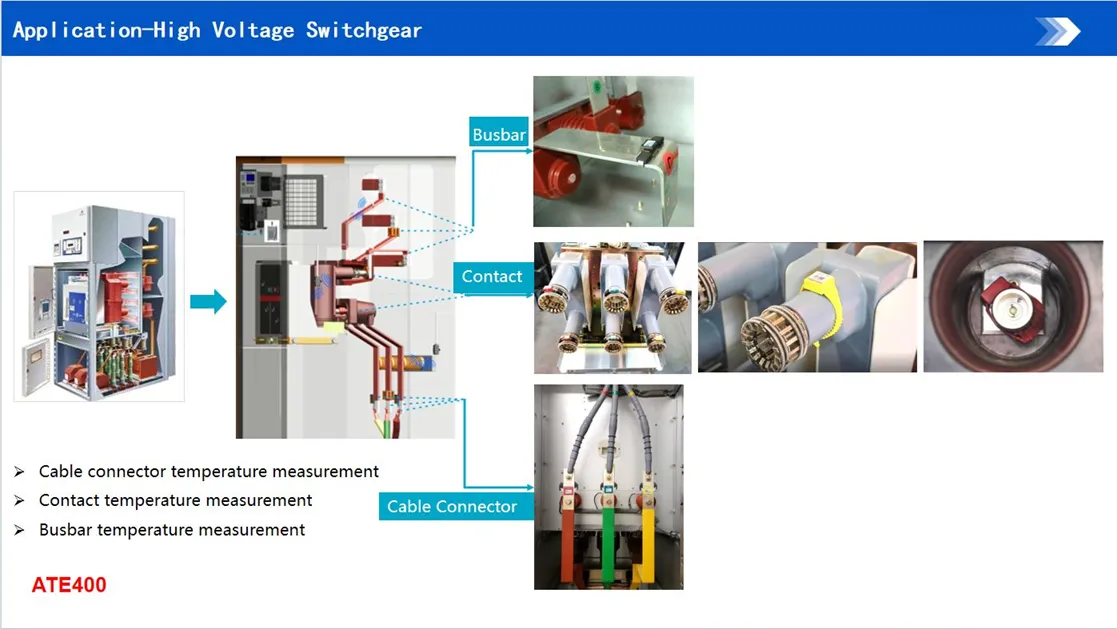

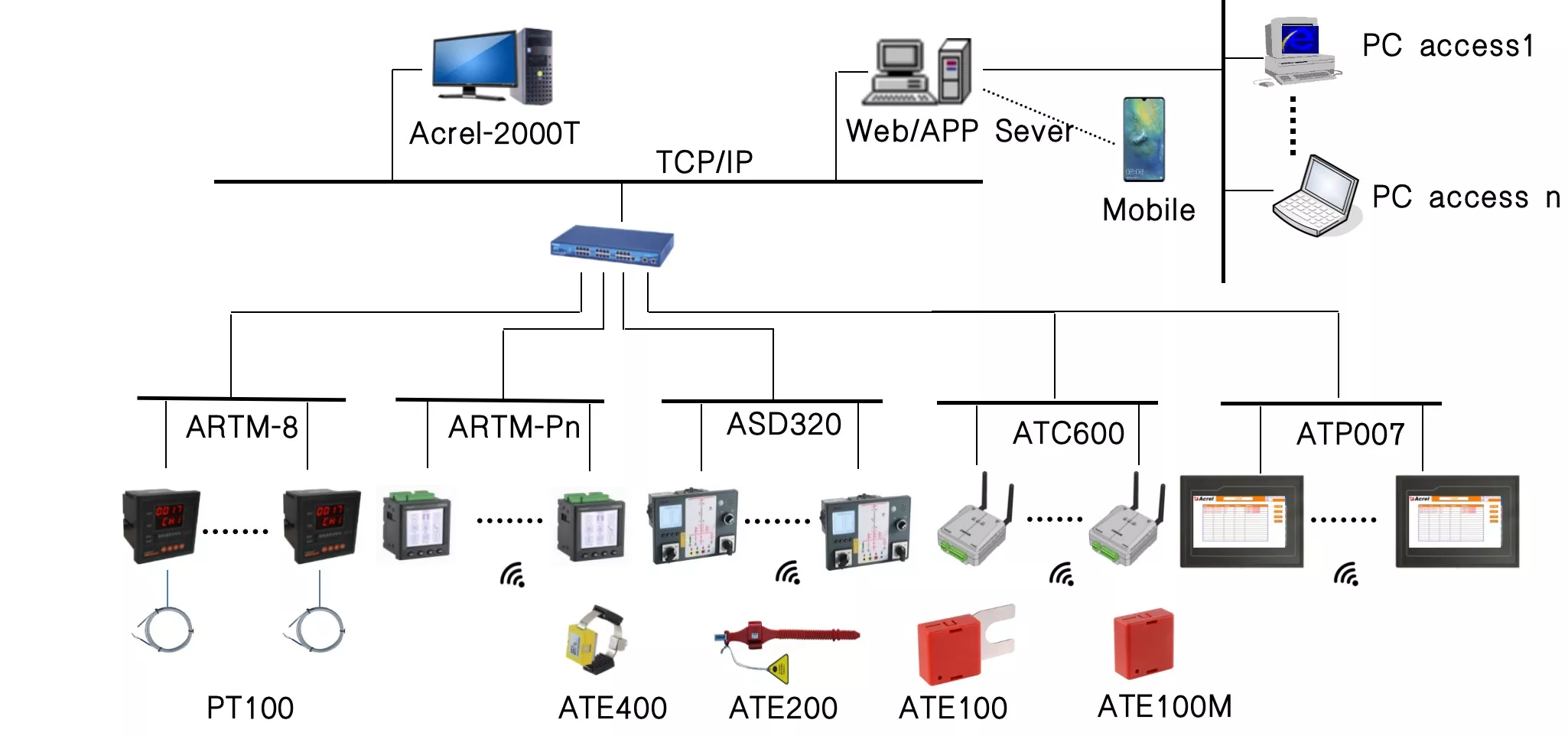

The project involves 1 switchgear, 8 substations and 4 pump houses in the park. The renovation objects include 32 transformers, 32 low-voltage incoming line cabinets, 185 low-voltage feeder cabinets, 68 capacitor cabinets, 9 DC panels, 14 water pumps, and the environment of the substations and pump houses. The platform is connected to more than 50 integrated protection devices, more than 300 multi-functional power meters, more than 60 power factor compensation controllers, nearly 4,000 electrical contact temperature sensors, 14 vibration sensors, 65 temperature and humidity sensors, more than 50 water immersion sensors, and nearly 30 smoke sensors. It also collects switch signals from more than 290 light signs, relays, circuit breakers, etc. through the IO module, monitors nearly 600 distribution circuits of the switch cabinet, and collects more than 80,000 various telemetry and telesignal quantities. An access control system is installed at the entrance of the substation, and 8 suspended rail-mounted intelligent inspection robots have been installed indoors after modification. The robots are equipped with visible light and infrared cameras, and the total length of the robot inspection track is more than 300 meters. All kinds of instruments and equipment installed on site are connected to the ANet intelligent gateway, which completes edge computing tasks such as protocol analysis, alarm generation, logic control, and local storage. The data is uploaded to the AcrelEMS platform via the fiber optic network. A large-screen display system is installed in the central substation to centrally monitor and uniformly manage the power supply and distribution operations of the entire park.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Jan 15, 2024

Wireless Temperature Monitoring in the Philippines

Jul 20, 2023

Energy management system Application in Cadillac