Acrel ABAT100 Series: Smart Lead-Acid Battery Monitoring Solution for Thailand’s Industrial Growth

Dec 21, 2025

In Thailand’s dynamic industrial landscape—where data centers, manufacturing plants, and critical infrastructure rely heavily on lead-acid batteries for backup power—unexpected battery failures can lead to costly downtime, safety hazards, and compliance risks. Acrel’s ABAT100 Series Battery Online Monitoring System emerges as a game-changing solution, blending cutting-edge technology with user-centric design to redefine battery management standards.

Why is lead-acid battery monitoring necessary?

1. International Standards Compliance Requirements for Data Centers

To meet the compliance requirements of international clients (such as Google's Bangkok data center and local operator True Data Center), leading data centers in Thailand generally adhere to the TIA-942 data center standard (a globally recognized standard for data center design and operation). This standard explicitly requires that:

"Data centers of Tier 3 and above must conduct real-time monitoring of individual battery banks' voltage, internal resistance, and temperature," and the monitoring system must be independent of the UPS host (to prevent monitoring failure due to UPS malfunction).

The localization of this international standard has led to mid-to-high-end data centers in Thailand proactively deploying additional lead-acid battery monitoring systems, rather than relying on policy mandates.

2. Operational Risk Management in the Telecommunications and Healthcare Industries

In Thailand, lead-acid battery failures in base stations of telecommunications operators (such as AIS and DTAC) and intensive care units (ICUs) of public hospitals can lead to serious consequences such as communication outages and medical equipment shutdowns.

Industry-specific maintenance guidelines (such as the "Base Station Power Supply Reliability Guidelines" of the National Telecommunications Commission of Thailand) clearly require "at least one battery health check per month." However, manual checks are inefficient and prone to errors. Therefore, companies generally choose 24-hour online monitoring equipment (such as the ABAT100-S single module) to achieve "real-time early warning + predictive maintenance" and reduce operational risks.

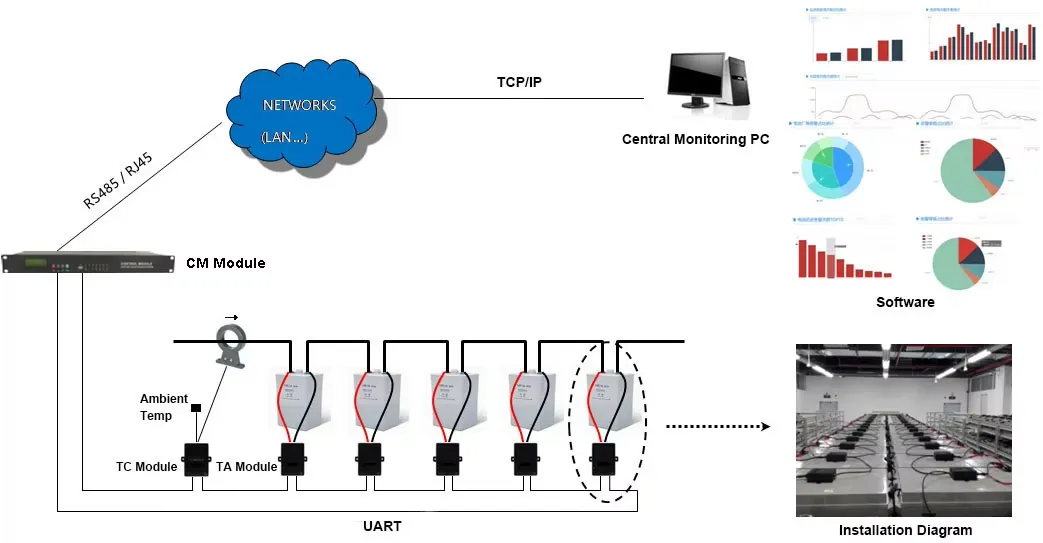

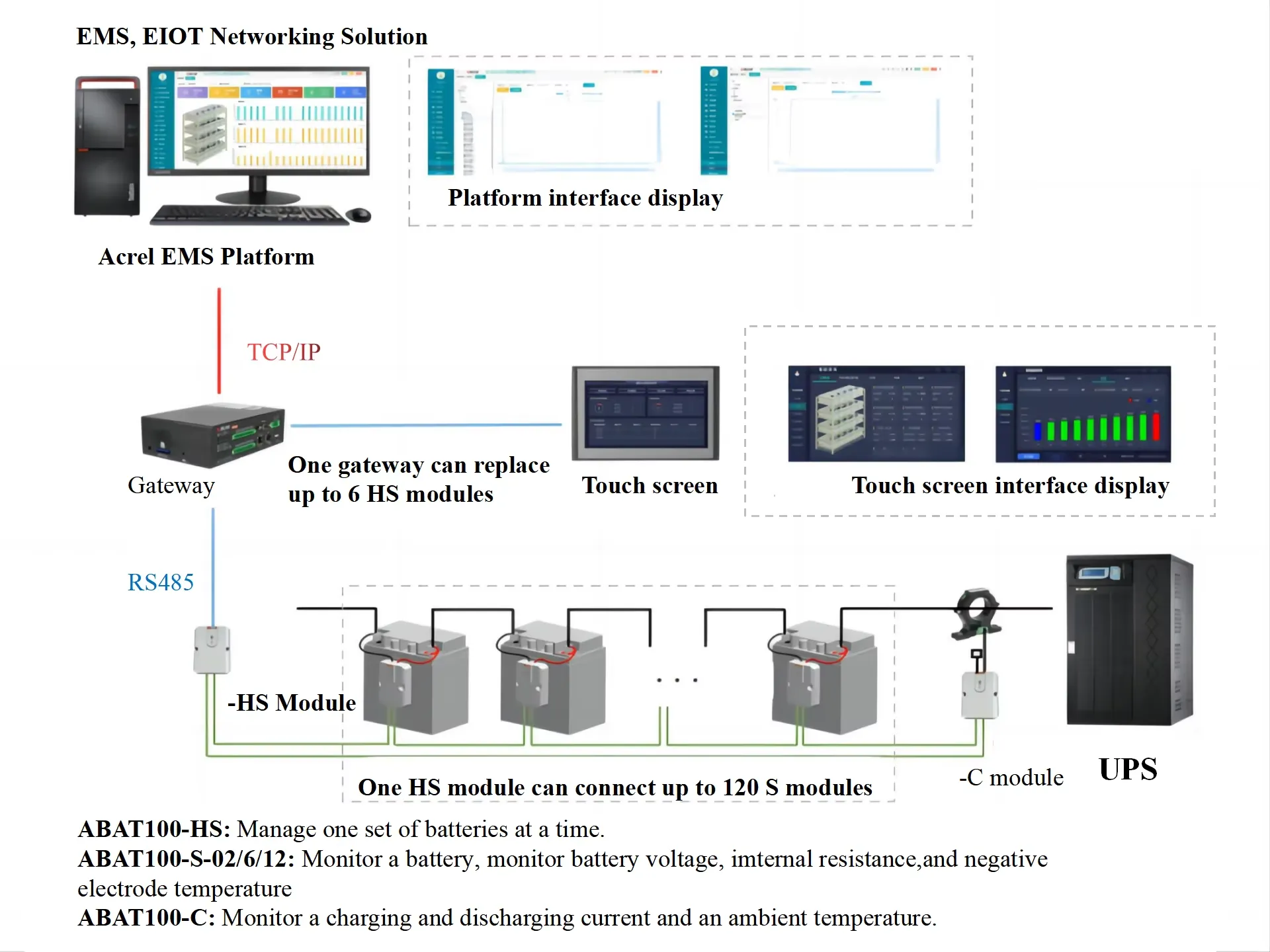

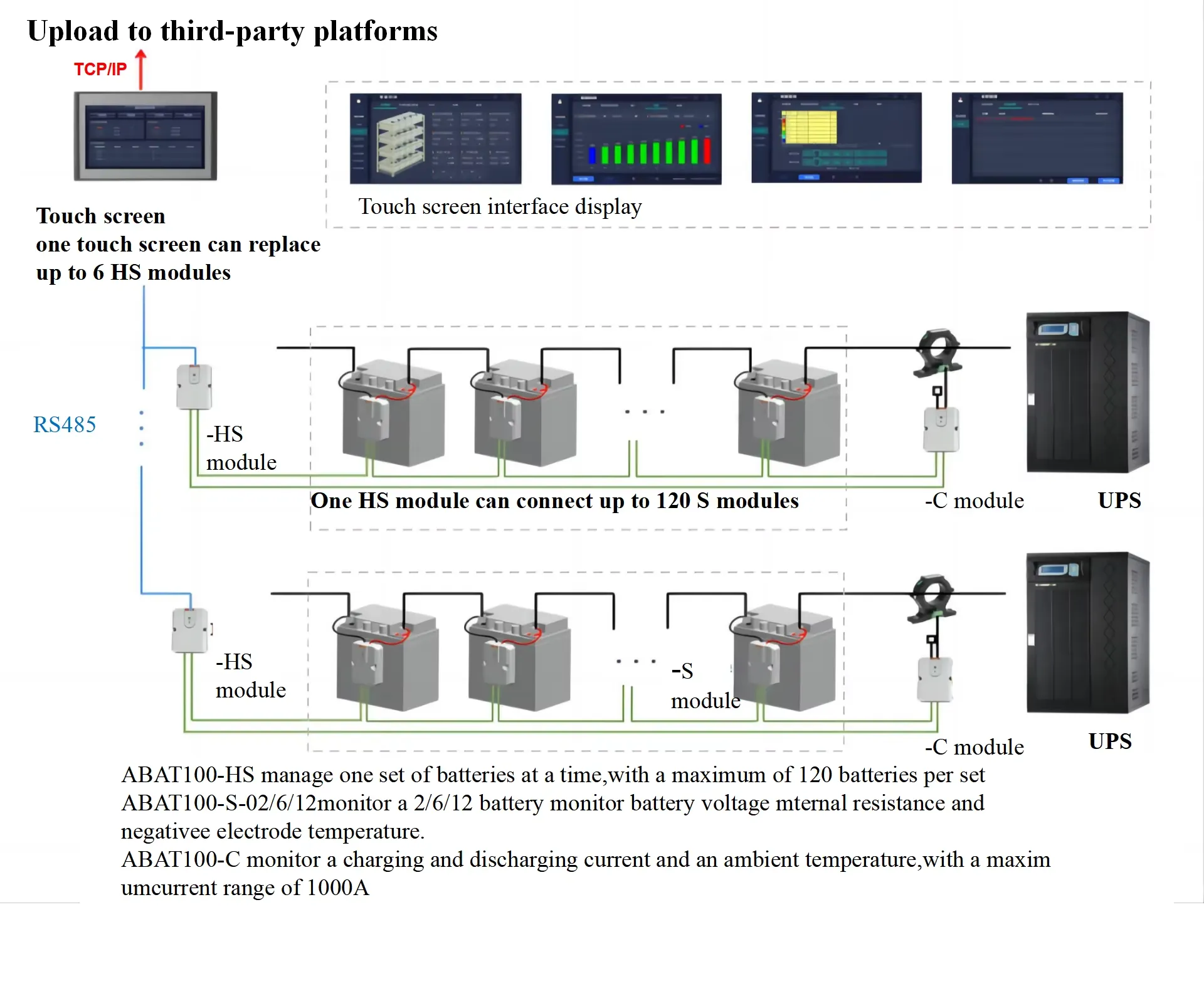

Designed to meet the rigorous ANSI/TIA-942 standard , the ABAT100 Series delivers comprehensive real-time monitoring of key battery metrics: voltage, internal resistance, internal temperature, state of charge (SOC), and state of health (SOH) . Its modular architecture—comprising ABAT100-S single battery monitoring modules, ABAT100-C current/temperature modules, and ABAT100-HS collectors—enables flexible deployment, supporting up to 960 cells across six battery strings . Installation and maintenance are streamlined, with plug-and-play functionality that minimizes operational disruption for Thai enterprises.

Beyond real-time tracking, the system’s intelligent early warning mechanism identifies deteriorating batteries at the earliest stage, allowing proactive replacement before failures occur . The centralized network management platform aggregates data for remote access, empowering maintenance teams to monitor battery performance anytime, anywhere—critical for Thailand’s geographically dispersed industrial facilities. By optimizing battery lifespan and reducing unplanned outages, the ABAT100 Series cuts operational costs while enhancing reliability for UPS systems, telecom base stations, and emergency power setups.

For more details,pls check:https://www.acrel.co.th/shop/acrel-abat100-lead-aacid-battery-pack-monitoring-device-1-1

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Nov 20, 2025

Protect your electrical circuits with ALP500.