Medical Isolation Power Supply System

Dec 04, 2023

IT System

Definition: The power supply is not grounded, and the equipment case is grounded

Protection: Monitoring system insulation resistance to ground

TT System

Definition: power grounding, equipment case grounding

Protection: monitoring system residual current to ground

The first letter indicates the status of the neutral point and ground of the power supply:

T - indicates that the neutral wire of the power supply is directly grounded;

I - indicates that the neutral wire of the power supply is not grounded or grounded with high impedance.

The second letter indicates the state of the load side and ground;

T - The leaking conductive part of the electrical device is directly grounded, and the grounding point is independent of the grounding point of the power supply terminal;

N - The exposed conductive part of the electrical device is directly electrically connected to the grounding point of the power supply terminal.

The third letter C indicates that the neutral line (N line) is shared with the protective zero line (PE line); the fourth letter S indicates that the neutral line (N line) is separated from the PE line

TN-S System: Poor Security & Continuity of Power Supply

1. In the grounding system, when the live wire earth fault occurs, the neutral & live wire is short-circuited to the ground, and the circuit breaker trips, which affects the continuity of the power supply.

2. Any electrical equipment powered by the TN system will generate a certain amount of leakage current, which poses a threat to medical staff and patients.

3. If the leakage current of the equipment is too large and exceeds the operating current of the leakage current protection circuit breaker, the circuit breaker will trip, which will also affect the continuity of the power supply.

IT System: Good Power Supply Security & Continuity

1. The IT system is not grounded. When any live wire ground fault occurs (the first time ground fault), the insulation monitor will report a ground fault, but the circuit breaker will not trip, and the system can continue to operate with the fault occurring.

2. Since the system is not grounded, the leakage current forms a loop through the distributed capacitance of the system. Under high capacitive reactance, the leakage current will be relatively small, and the normal system leakage current is below microamperes.

3. For medical IT systems, the IEC standard requires that the input and output circuit breakers of the IT system are not allowed to have an overload protection function, and the power supply will not be interrupted when overloaded.

|

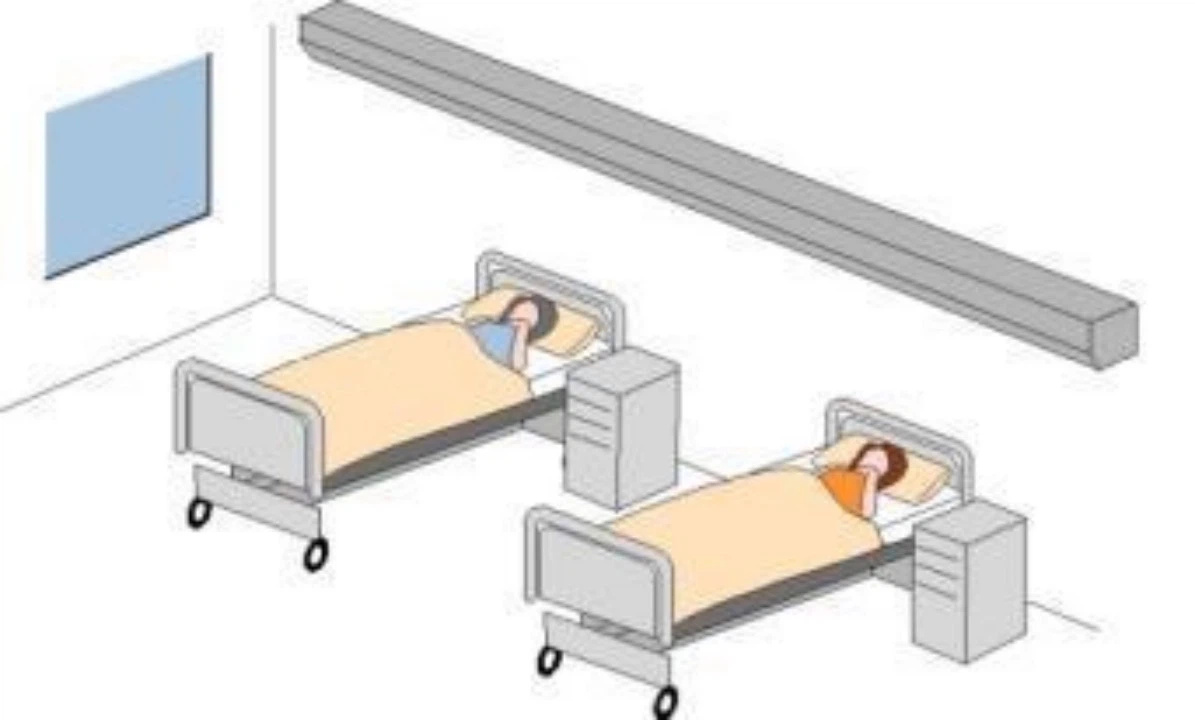

Medical Venue of Class 0 |

Medical Venue of Class 1 |

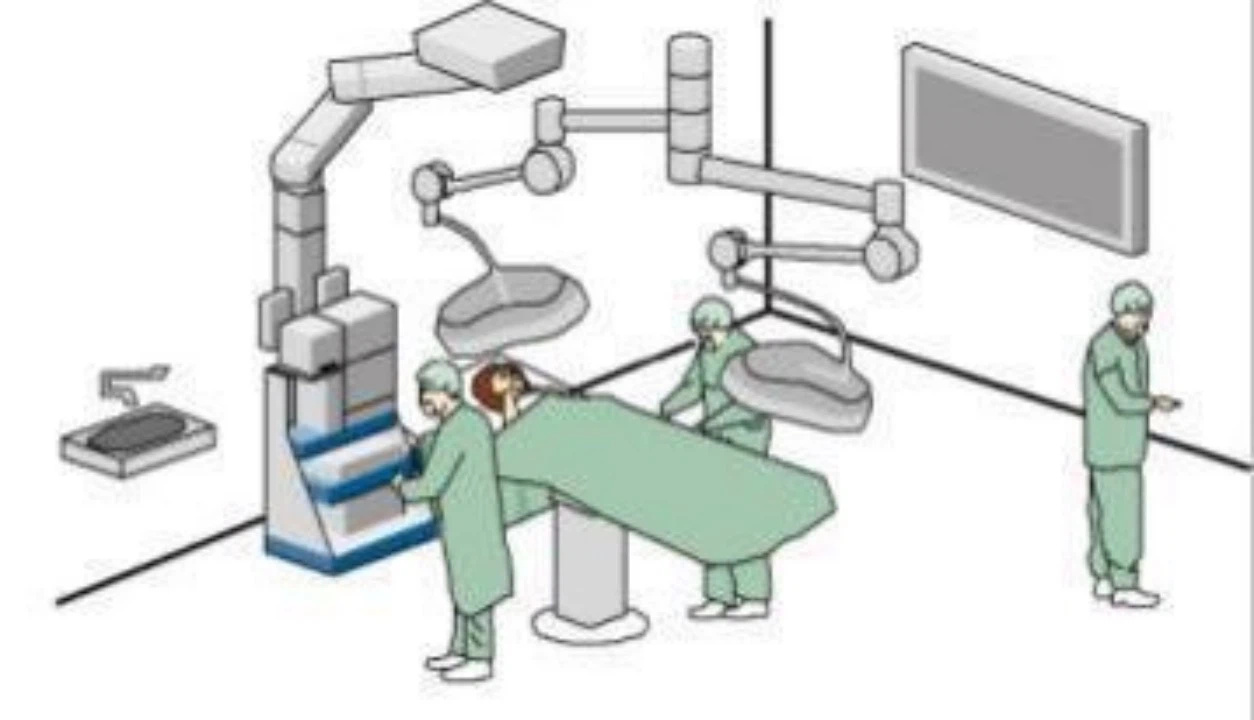

Medical Venue of Class 2 |

|

|

Application |

Such places do not have electrical equipment that directly contacts the patient's body |

The electrical facilities in such places are mainly used for the patient's body surface contact |

Electrical facilities in such places are mainly used for patient-invasive treatment methods and life support system equipment. |

|

Power Supply Method |

A Power failure will not directly cause or affect the life safety of patients |

A power interruption will not pose a direct safety threat to patients during diagnosis and treatment. |

Unexpected interruption of power supply will directly affect the life safety of patients |

|

Examples |

▪ Massage Therapy Room |

▪ Physiotherapy room |

▪ Operating Room |

|

|

|

|

|

AITR Series Medical isolation transformer

◆ Isolating transformers for medical IT systems

◆ Double insulation treatment, Electrostatic shielding layer

◆ PT100 temperature sensor

◆ Rated power: 3.15…10KVA

◆ CE mark

AIM-M10 Medical Intelligent Insulation Monitor

◆ Insulation monitoring for medical IT systems

◆ Load and temperature monitoring of the isolation transformer

◆ Device disconnection monitoring

◆ LED indicators: On, Insulation, Overload, Overtemp

◆ One Alarm relay output

◆ Test button

◆ One RS485,MODBUS-RTU

AIM-M100 Medical Intelligent Insulation Monitor

◆ Insulation monitoring for medical IT systems

◆ Load and temperature monitoring of the isolation transformer

◆ Device disconnection monitoring

◆ LCD indicators: On, Insulation, Overload, Overtemp

◆ Two Alarm relay output

◆ Test button

◆ One RS485,MODBUS-RTU

AIM-M200 Medical Intelligent Insulation Monitor

◆ Insulation monitoring for medical IT systems

◆ Load and temperature monitoring of the isolation transformer

◆ Device disconnection monitoring

◆ LED indicators: On, Insulation, Overload, Overtemp

◆ Two Alarm relay output

◆ Test button

◆ Insulation fault location

◆ RS485 (MODBUS-RTU) + CAN (custom protocol)

AID10 Alarm and Display Instrument

◆ Remote monitoring of one set of AIM-M10 insulation monitor

◆ LED indicators: On, Insulation, Overload, Overtemp

◆ Mute button

◆ Test button

◆ Power supply: DC24V

◆ RS485,MODBUS-RTU

AID120 Alarm and Display Instrument

◆ Remote monitoring of one set of AIM-M10 insulation monitor

◆ LCD indicators: On, Insulation, Overload, Overtemp

◆ Mute button

◆ Test button

◆ Power supply: DC24V

◆ RS485,MODBUS-RTU

ASG150 Signal Generator

◆ Generating Fault Location Signal

◆ Detection of L1 and L2 disconnection

◆ LED indicators: On, Comm, L1, L2, Fault

◆ CAN bus, custom protocol

◆ Power supply: DC24V

AIL150-4/-8 Insulation Fault Locator

◆ Insulation fault location in AC IT systems

◆ AIL150-4: 4 measuring channels

◆ AIL150-8: 4 measuring channels

◆ LED indicators: On, Comm, L1…L8

◆ CAN bus, custom protocol

◆ Power supply: DC24V

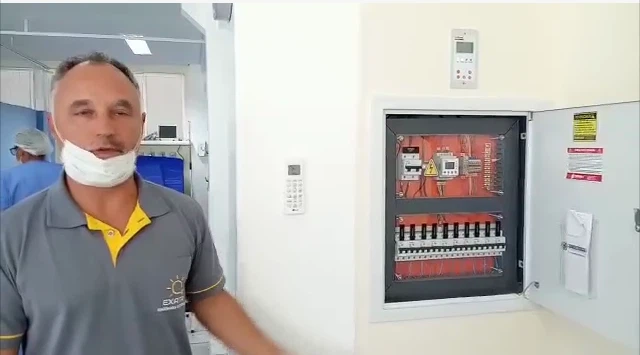

Using:

1) AITR series medical isolation transformer;

2) AIM-M10 medical intelligent insulation monitor;

3) AKH-0.66P26 current transformer;

4) AID10 external alarm and display instrument

Using:

1) AITR series medical isolation transformer;

2) AIM-M100 medical intelligent insulation monitor;

3) AKH-0.66P26 current transformer;

4) ACLP10-24 dc power module;

5) AID series (AID120, AID150) external alarm and display instrument

Using:

1) AITR series medical isolation transformer

2) AIM-M300(or AIM-M300/SG) medical intelligent insulation monitoring device;

3) AKH-0.66P26 current transformer;

4) AIL150-4/AIL150-8 /AIL160-6 insulation fault locator;

5) HDR-60-24 power module;

6) AID150 centralized alarm and display device

Using:

1) AITR series medical isolation transformer;

2) AIM-M200 medical intelligent insulation monitoring instrument;

3) AKH-0.66P26 current transformer;

4) AIL100-4/AIL100-8 insulation fault locator;

5) ASG100 test signal generator;

6)HDR-60-24 power module;

7)AID200 centralized alarm and display instrument

Applicable to TN-S systems in Class 1 and Class 2 medical places such as medical delivery rooms, hemodialysis centers, emergency rooms, etc., it can monitor the leakage current of 12 main lines or each terminal branch, and has an over-value alarm function;

1) Leakage monitoring range is 1mA~5A; alarm value range: 6mA~1A;

2) 1 channel RS485 communication, which can be used for data remote monitoring;

3) 1 channel relay alarm output.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Mar 27, 2023

Prepayment Cloud Platform Solution

Mar 22, 2023

Acrel Hall Effect Sensor Solution